Lost Foam Casting

DISAMATIC is an automatic production line used for fast manufacturing of sand molds for sand casting. This process is commonly used to mass manufacture of metal castings for the automotiveand machine industry.

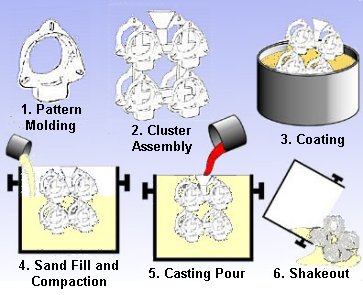

The basic steps of the lost foam casting process are:

1. Pattern molding

Production of patterns in a precision tool with expendable polystyrene (EPS) beads (Heat expands and bonds the beads to produce a rigid pattern).

2. Cluster assembly

Assembly of the patterns onto a gating system.

3. Coating

Coating the pattern assembly with a refractory wash coat.

4. Sand fill and compaction

Forming the mold by compacting dry sand around the coated pattern in a one piece flask.

5. Casting four

Pouring the metal into the mold with vaporization of the EPS pattern.

6. Shakeout

Shakeout, cut off, finishing, and inspection of the casting.

NOTICE OF LUNAR NEW YEAR HOLIDAY IN 2013

Casting Industry

The technology of embryo manufacturing in the mechanical industry in Vietnam

Siemens to build four casting plants in Vietnam